Mangueira de Transferência de Óleo Resistente a UV, Resistente às Intempéries, Fácil Instalação, Anti-Abrasão

Descrição

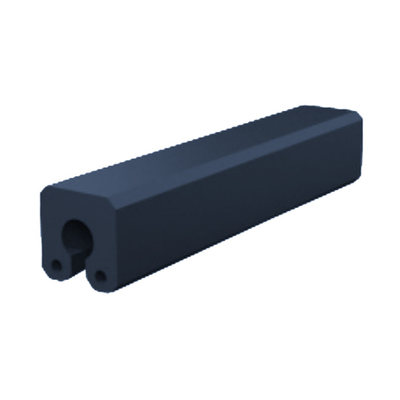

As mangueiras STS são mangueiras flexíveis de alto desempenho projetadas para lidar com fluidos de alta pressão em uma variedade de aplicações industriais, automotivas, de construção e marítimas. Projetadas para durabilidade, segurança e confiabilidade, as mangueiras STS são fabricadas com materiais sintéticos premium reforçados com fios de aço ou tramas têxteis, garantindo resistência à pressão, flexibilidade e longevidade ideais. Essas mangueiras são adequadas para sistemas hidráulicos, direção hidráulica, sistemas de freio, máquinas offshore e muitas outras aplicações exigentes.

Os principais benefícios das mangueiras STS incluem desempenho sem vazamentos, alta resistência à abrasão, estabilidade química e adaptabilidade a condições ambientais extremas. Ao fornecer um conduto confiável para transferência de fluidos, as mangueiras STS desempenham um papel fundamental na melhoria da eficiência operacional, segurança e vida útil do equipamento.

Estudo de Caso: Sistemas Hidráulicos de Máquinas Industriais

Um fabricante líder de máquinas de moldagem por injeção integrou mangueiras STS em seus circuitos hidráulicos. A resistência à alta pressão e a flexibilidade das mangueiras permitiram que as máquinas operassem continuamente sob cargas pesadas. O tempo de inatividade de manutenção diminuiu em 30% e a eficiência operacional geral aumentou devido à transferência confiável de fluidos fornecida pelas mangueiras STS.

Especificações

| Material |

PTFE, Fio de Aço Galvanizado, Tecido de Poliéster Revestido com PVC |

| Nome do Produto |

Mangueira STS |

| Tamanho |

HM-SH78 |

| Fio Interno |

Aço Inoxidável 316 |

| Revestimento |

Poliamida |

| Carcaça |

Tecidos de poliamida, filmes de poliéster |

| Fio Externo |

Aço Inoxidável 316 |

| Pressão de Trabalho |

10 bar a 21 bar |

| Comprimento Máximo |

40 metros |

| Amostra |

Disponível |

| Tempo de entrega |

Normalmente 3-5 dias |

| Modelo |

Dimensões |

Pressão de Trabalho |

Fator de Segurança |

Raio de Curvatura |

Peso |

Comprimento |

| Composto |

[mm] |

[polegada] |

[bar] |

[psi] |

[kg] |

[m] |

| HM-SH20 |

20 |

3/4" |

16 |

230 |

6:1 |

80 |

0.8 |

40 |

| HM-SH25 |

25 |

1" |

16 |

230 |

6:1 |

100 |

1 |

40 |

| HM-SH32 |

32 |

11/4" |

16 |

230 |

6:1 |

125 |

1.3 |

40 |

| HM-SH40 |

40 |

11/2" |

16 |

230 |

6:1 |

140 |

1.5 |

40 |

| HM-SH50 |

50 |

2" |

16 |

230 |

6:1 |

180 |

2.5 |

40 |

| HM-SH65 |

65 |

21/2" |

16 |

230 |

6:1 |

200 |

3.3 |

40 |

| HM-SH80 |

80 |

3" |

16 |

230 |

6:1 |

260 |

4 |

40 |

| HM-SH100 |

100 |

4" |

16 |

230 |

6:1 |

380 |

6.8 |

40 |

| HM-SH125 |

125 |

5" |

16 |

230 |

6:1 |

440 |

9.2 |

40 |

| HM-SH150 |

150 |

6" |

16 |

230 |

6:1 |

500 |

13.2 |

40 |

| HM-SH200 |

200 |

8" |

16 |

230 |

6:1 |

750 |

18 |

40 |

| HM-SH250 |

250 |

10" |

16 |

230 |

6:1 |

900 |

26 |

25 |

| *Observação: Vários tamanhos podem ser personalizados de acordo com os requisitos. |

Características

Resistência a Alta Pressão

As mangueiras STS são projetadas para suportar pressões hidráulicas extremas. O tubo interno, reforçado com fio de aço ou tramas têxteis de alta resistência, evita estouros e vazamentos, mesmo sob condições contínuas de alta carga. Isso garante a segurança dos operadores e equipamentos, mantendo o desempenho consistente em sistemas hidráulicos.

Design Flexível e Leve

Apesar de sua capacidade de alta pressão, as mangueiras STS permanecem altamente flexíveis, facilitando a instalação em layouts de máquinas confinados ou complexos. O design leve reduz o estresse nas conexões e componentes conectados, aumentando a eficiência geral do sistema e reduzindo o consumo de energia.

Resistência à Abrasão e Desgaste

A camada externa das mangueiras STS é feita de materiais sintéticos duráveis, resistentes a cortes, abrasões e impactos mecânicos externos. Essa durabilidade estende a vida útil em ambientes agressivos, como canteiros de obras, plantas industriais ou operações marítimas, reduzindo a frequência de substituições.

Resistência Química a Óleo e Temperatura

As mangueiras STS mantêm a integridade e o desempenho quando expostas a óleos hidráulicos, combustíveis e uma ampla gama de produtos químicos. Elas também funcionam de forma confiável em temperaturas extremas, desde o frio abaixo de zero até operações industriais de alta temperatura, garantindo a transferência ininterrupta de fluidos em diversas condições.

Aplicação

Transferência de Petróleo Bruto Entre Navios

As mangueiras STS são comumente usadas em operações de transferência de petróleo bruto de navio para navio (STS). Elas lidam com grandes volumes de petróleo bruto durante o carregamento ou descarregamento entre petroleiros, garantindo um fluxo seguro, flexível e eficiente em comparação com braços de carregamento rígidos.

Transferência de Produtos de Petróleo Refinado

Essas mangueiras são usadas para transferir gasolina, diesel, combustível de aviação e outros produtos de petróleo refinado entre navios ou entre instalações de navios e terra. Elas são projetadas para resistir à permeação de óleo e combustível e manter alta capacidade de vazão.

Transferência de GNL e GLP

Mangueiras STS criogênicas especializadas são empregadas para transferir gás natural liquefeito (GNL) ou gás de petróleo liquefeito (GLP). Elas são construídas para suportar temperaturas extremamente baixas e manter a flexibilidade durante operações offshore ou em terminais.

Por que escolher nossa empresa

Materiais de Alta Qualidade e Fabricação Avançada

Usamos borrachas sintéticas premium, fibras de alta resistência e reforço de aço para produzir mangueiras que atendem e superam os padrões internacionais. Processos de fabricação avançados garantem qualidade, durabilidade e confiabilidade consistentes.

Soluções Personalizáveis

Nossas mangueiras podem ser adaptadas aos requisitos específicos do cliente, incluindo comprimento, diâmetro, classificação de pressão e composição do material. Essa flexibilidade garante o desempenho ideal para qualquer aplicação, desde máquinas industriais até operações marítimas.

Suporte Técnico e Serviço

Fornecemos suporte técnico abrangente de pré-venda e pós-venda, incluindo orientação sobre seleção, instalação e manutenção de mangueiras. Nossa equipe de especialistas garante que os clientes maximizem a vida útil e o desempenho de suas mangueiras.

Histórico Comprovado e Presença Global

Com anos de experiência na fabricação de mangueiras hidráulicas e uma ampla rede de clientes satisfeitos em todo o mundo, nossos produtos demonstraram confiabilidade e desempenho superior em aplicações industriais, automotivas, de construção e marítimas.

Perguntas frequentes

P1: Qual é a pressão máxima de operação das mangueiras STS?

A1: Dependendo do modelo e do tipo de reforço, as mangueiras STS podem suportar pressões que variam de 2000 PSI a mais de 6000 PSI, adequadas para a maioria das aplicações hidráulicas e industriais.

P2: As mangueiras STS podem ser usadas em temperaturas extremas?

A2: Sim, as mangueiras STS são projetadas para funcionar em uma ampla faixa de temperatura, normalmente de -40°C a +125°C, sem comprometer a flexibilidade ou a resistência.

P3: As mangueiras STS são resistentes a produtos químicos e óleos?

A3: Absolutamente. O tubo interno é feito de borracha sintética ou materiais compatíveis com fluidos hidráulicos, óleos, combustíveis e uma ampla gama de produtos químicos industriais, minimizando o risco de degradação.

P4: Com que frequência as mangueiras STS devem ser substituídas?

A4: O intervalo de substituição depende das condições de operação, pressão e exposição ambiental. No entanto, sua resistência à abrasão e produtos químicos estende significativamente a vida útil em comparação com as mangueiras convencionais, muitas vezes durando vários anos sob uso industrial normal.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!