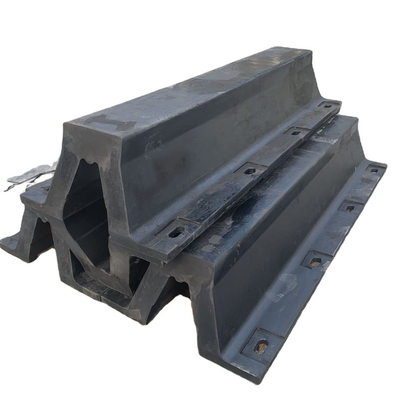

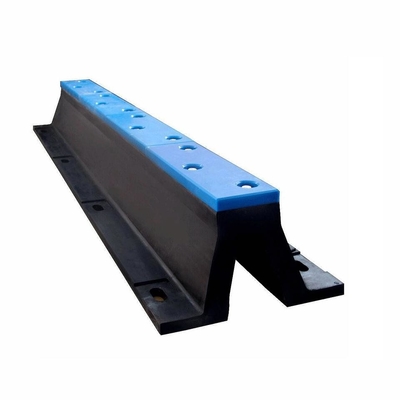

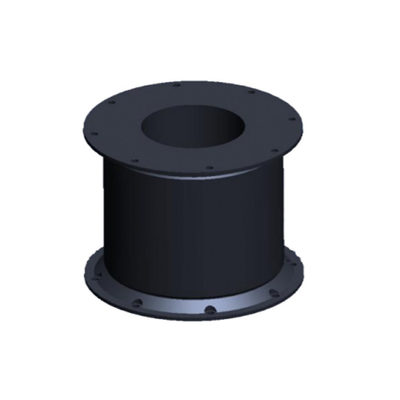

Exceptional Energy Dissipation for High Frequency Docking

The fender’s internal air chamber allows progressive compression, effectively absorbing impact energy during frequent berthing events. This prevents stress spikes on vessel hulls and dock structures, maintaining operational continuity in high-traffic ports.

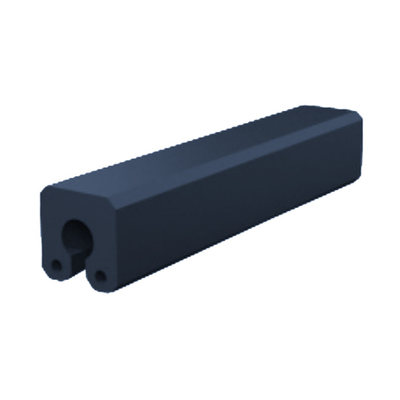

Ultra Resilient Reinforced Cord Layers

Multiple layers of synthetic tire-cord fabric embedded in high-quality rubber provide superior tensile strength and fatigue resistance. This reinforcement maintains the fender’s cylindrical shape and prevents delamination under repeated compression cycles, ensuring long-term stability in high-load environments.

Durable and Weather Resistant Rubber Shell

The external rubber layer is formulated for maximum resistance against ozone, UV radiation, saltwater, and abrasion. The seamless design minimizes wear and tear during repeated docking of large vessels, while optional chain-tire nets provide additional mechanical protection for extreme impact scenarios.

Flexible Deployment and Pressure Adjustment

Hongruntong pneumatic fenders are lightweight and easily installed or repositioned. Air pressure can be adjusted to optimize stiffness for varying vessel sizes and berthing conditions, ensuring consistent energy absorption across multiple operational scenarios.

Applications

High Traffic Container Terminals

Provides critical energy absorption for repeated docking of large container ships and feeder vessels, protecting quay structures and hulls.

Ship to Ship Transfer Operations

Ideal for oil, LNG, and bulk cargo transfers where vessels are in close proximity and require precise impact cushioning.

Floating or Temporary Berths in High-Use Ports

Supports modular berthing solutions that require rapid deployment and high durability under continuous loading cycles.

Why Choose Hongruntong Marine

Expertise in Heavy-Duty Marine Solutions

Hongruntong Marine has decades of experience supplying high-capacity Yokohama pneumatic fenders to the busiest ports worldwide. Our products are engineered to sustain frequent, high-energy berthing without compromising safety or structural integrity.

Advanced Material Formulation and Manufacturing

We utilize specialized rubber compounds and high-tensile cord fabrics with advanced vulcanization techniques. This ensures optimal elasticity, fatigue resistance, and long-term stability under extreme usage conditions.

Tailored Engineering and Simulation-Based Design

Fenders are custom-designed for vessel size, berthing energy, and docking frequency. Hongruntong employs finite element analysis to simulate multiple impact scenarios, optimizing fender dimensions, inflation pressure, and reinforcement layers for each project.

Comprehensive Support and Global Service Network

From delivery to installation, inspection, and lifecycle maintenance, Hongruntong Marine provides complete support. Our global logistics network ensures rapid spare parts supply and technical assistance, minimizing downtime and maximizing operational efficiency.

FAQ

1. How durable are Yokohama fenders in high-frequency docking?

They are designed to withstand thousands of berthing cycles without structural failure, maintaining consistent energy absorption and low reaction force.

2. Can these fenders handle ultra-large container ships?

Yes, the reinforced cord layers and adjustable internal air pressure allow fenders to absorb energy from vessels exceeding 200,000 DWT.

3. Are protective nets mandatory for all installations?

Optional chain-tire nets are recommended for high-energy or high-frequency berthing to prolong lifespan and protect the outer shell.

4. How frequently should maintenance inspections occur?

Visual inspections and pressure checks are recommended monthly in high-use environments, with additional checks after extreme impact events.

5. Are these fenders suitable for floating offshore berths?

Yes, the floating design, flexible deployment, and customizable pressure settings make them ideal for temporary or floating offshore docking solutions.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!