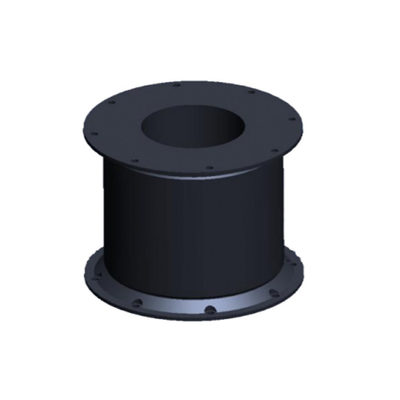

High Energy Absorption and Low Reaction Force

The fender uses compressed air as an energy-absorbing medium, allowing large deflection while maintaining a low reaction force. This feature ensures that both the vessel hull and quay remain undamaged during impact. The unique internal pressure dynamics enable superior cushioning even under heavy berthing speeds.

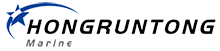

Reinforced Layered Structure for Maximum Strength

Each fender is constructed with multiple layers of synthetic tire-cord fabric embedded between thick rubber sheets. This design provides exceptional tensile strength, resists fatigue, and prevents tearing under repeated compression. The reinforced body distributes load evenly, extending the fender’s service life even under demanding port conditions.

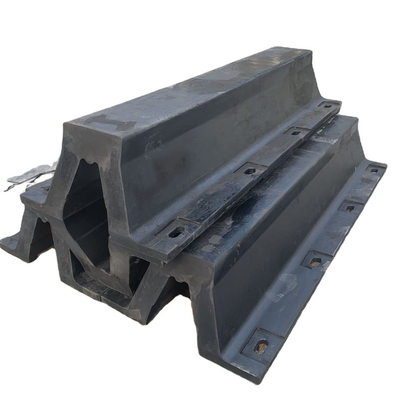

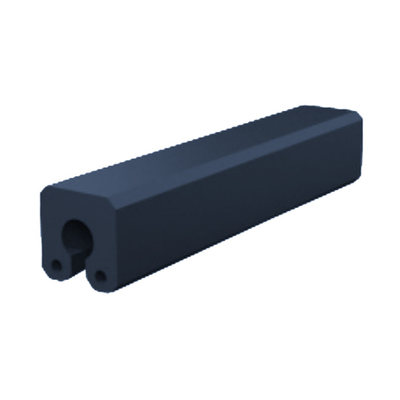

Durable Outer Rubber Shell

The external layer is composed of weather-resistant, abrasion-resistant, and UV-resistant rubber compounds. It withstands harsh marine environments, including saltwater, oil, and ozone exposure. This durable cover prevents surface cracking and aging, ensuring reliable long-term performance with minimal maintenance.

Ease of Installation and Pressure Maintenance

Hongruntong pneumatic fenders are lightweight, easy to deploy, and can be adjusted by simply changing internal air pressure. Optional chain and tire nets provide additional mechanical protection. Maintenance is simple, requiring only periodic pressure checks and external inspections, significantly reducing operational downtime.

Applications

Commercial Ports and Terminals

Ideal for protecting container ships, bulk carriers, and tankers during berthing, minimizing collision damage and increasing berth safety.

Ship to Ship Transfer Operations

Used in offshore bunkering, oil transfer, and cargo handling, providing a flexible buffer between two moving vessels in dynamic sea conditions.

Offshore Platforms and Floating Docks

Provides stable cushioning for offshore structures, floating piers, and temporary berthing installations exposed to waves and tidal movements.

Why Choose Hongruntong Marine

Advanced Manufacturing Expertise

Hongruntong Marine uses precision-engineered rubber compounds, multi-layer cord reinforcement, and advanced vulcanization technology to ensure consistent quality and strength. Each fender meets ISO 17357 standards, guaranteeing performance stability and air-tight integrity.

Strict Quality Control and Testing

Every fender undergoes burst pressure testing, airtightness checks, and deformation performance verification. The company follows strict inspection protocols for material hardness, tensile strength, and adhesion, ensuring product reliability in demanding marine operations.

Customizable Solutions for Global Projects

Fenders can be custom-designed for diameter, length, inflation pressure, and end fittings. Options include sling-type, chain-tire net type, and customized coatings for specific vessel applications. Hongruntong’s engineering team provides simulation-based designs for optimal safety and efficiency.

Global Service and Long Term Support

Hongruntong Marine offers full life-cycle service, including installation guidance, periodic inspection, reconditioning, and pressure monitoring. A worldwide logistics network ensures timely spare parts supply and technical assistance, helping clients reduce total ownership costs.

FAQ

1. How long does a Yokohama fender last?

Typically 10 to 15 years under standard operating conditions, depending on impact frequency, environment, and maintenance quality.

2. Can the fender operate in extreme weather?

Yes. The materials maintain elasticity and strength in high UV, salinity, and temperature variations from –50 °C to +70 °C.

3. How is the fender maintained?

Regularly check internal air pressure, inspect for cracks or surface damage, and clean marine growth. Maintain correct pressure for stable performance.

4. Can fenders be repaired if damaged?

Minor surface wear can be patched. Major structural or bladder damage should be serviced by Hongruntong’s repair facilities to ensure safety compliance.

5. What types of fittings are available?

Options include flanged ends, swivel eyes, chain-tire nets, or sling-type designs depending on berthing requirements and vessel size.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!