Berthing Fender Strong Impact Resistance Weather Resistance High Rebound

Description

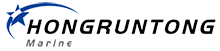

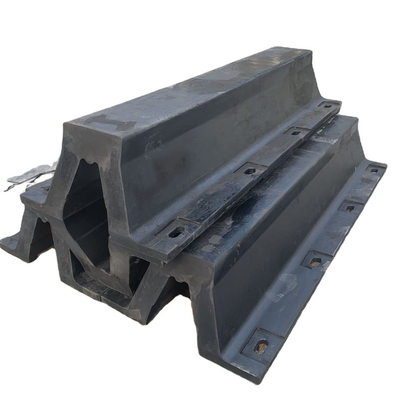

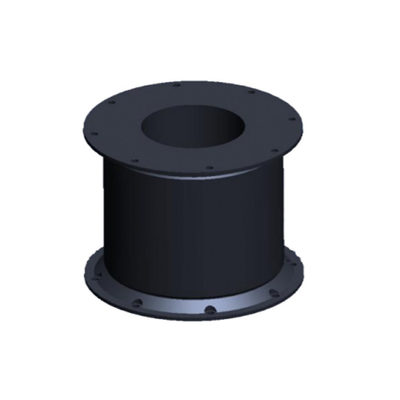

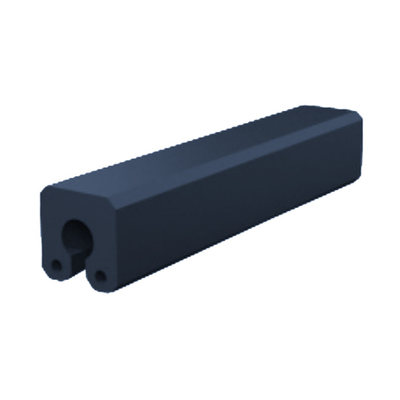

The D Type Fender is a robust marine fender designed to provide superior protection for vessels, docks, and offshore structures. Manufactured from high-grade rubber and reinforced with resilient inner layers, these fenders are engineered to absorb impact energy efficiently, minimizing damage during berthing operations. Typical dimensions range from 300mm to 1200mm in height, with lengths and diameters tailored to vessel size, and they can be customized according to client specifications.

The D Type Fender features an innovative convex outer profile and a flat mounting surface, enabling maximum contact with hulls while reducing point pressure and friction. Its material composition ensures high compressive strength, excellent elasticity, and resistance to wear, UV radiation, and harsh saltwater environments. The fender is suitable for various vessel types, including cargo ships, oil tankers, container ships, ferries, and yachts. By combining durability, performance, and ease of installation, the D Type Fender effectively safeguards maritime assets while optimizing operational efficiency.

Case Study

Project: Offshore Docking Facility, Singapore

A Singapore-based marine contractor was tasked with upgrading a busy offshore docking facility servicing mid-sized cargo ships up to 20,000 DWT. Frequent docking operations caused hull scratches, paint abrasion, and occasional minor structural damage to vessels. Hongruntong Marine proposed installing D Type Fenders along the quay to mitigate these issues.

The fenders were manufactured with reinforced rubber and tested for compressive load up to 3,000 kN/m². Installation involved both vertical and horizontal placements to ensure uniform energy absorption across the hull surface. During a 12-month operational period, the fenders successfully absorbed repeated berthing impacts, preventing any hull damage, reducing maintenance costs by an estimated 25%, and increasing docking efficiency by 18%. Feedback from ship operators highlighted the fender’s reliability under high-frequency use, and the design proved easily replaceable, ensuring long-term operational repeatability.

Project: Medium Sized Ferry Port, Indonesia

In a ferry terminal in Indonesia handling vessels of 5,000–8,000 DWT, conventional cylindrical fenders failed to prevent hull scrapes during tidal variations. Hongruntong Marine installed D Type Fenders with a wider contact surface and integrated UV-resistant rubber. Within six months, incidents of hull damage were eliminated, and docking operations became faster and safer. Port management noted the reduction in maintenance downtime and praised the fender’s durability under tropical marine conditions.

Specifications

| Place of Origin |

China |

| Product Name |

Dock Rubber Fender |

| Type |

D Shape Type |

| Processing Service |

Compression Moulded |

| Color |

Black (More Colors Optional) |

| Material |

Smooth NR |

| Performance |

Excellent chemical and Physical Property |

| Logo |

Customer's Request |

| Application |

Port, Dock, Boat |

| Type |

Specifications |

| H |

B |

L |

Holes |

Q |

C |

h |

D |

d |

| D150x150x1000 |

150 |

150 |

1000 |

3 |

350 |

150 |

25 |

40 |

24 |

| D200x200x1000 |

200 |

200 |

1000 |

3 |

353 |

150 |

35 |

55 |

30 |

| D200x200x3000 |

200 |

200 |

3000 |

8 |

400 |

100 |

35 |

55 |

30 |

| D250x250x1000 |

250 |

250 |

1000 |

3 |

350 |

150 |

35 |

60 |

30 |

| D250x250x3000 |

250 |

250 |

3000 |

8 |

400 |

100 |

35 |

60 |

30 |

| D300x300x1000 |

300 |

300 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x300x3000 |

300 |

300 |

3000 |

8 |

400 |

100 |

40 |

65 |

32 |

| D300x360x1000 |

300 |

360 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x360x3000 |

300 |

360 |

3000 |

8 |

400 |

100 |

40 |

65 |

40 |

| D400x400x1000 |

400 |

400 |

1000 |

3 |

400 |

150 |

55 |

80 |

32 |

| D400x400x3000 |

400 |

400 |

3000 |

8 |

400 |

100 |

55 |

80 |

40 |

| D500x500x1000 |

500 |

500 |

1000 |

3 |

350 |

150 |

90 |

97 |

45 |

| D500x500x3000 |

500 |

500 |

3000 |

8 |

400 |

100 |

90 |

97 |

45 |

| TECHNICAL DATA |

| PROPERTIES |

TEST STANDARD |

VALUES |

| Compound |

- |

NR / SBR |

| Density (Specific Gravity) |

DIN 53505 |

1200 kg/m3 |

| Tensile Strength |

DIN 53504 |

≥16 MPa |

| Elongation at Break |

DIN 53504 |

≥350% |

| Tear Resistance (23°C) |

DIN 53507 |

≥80 N/cm |

| Abrasion Resistance |

DIN 53516 |

≤100mm3 |

| Compression Set (24hrs @ 70°C) |

DIN 53517 |

≤40% |

| Ozone Resistance (ppm 20% 72hrs @ 40°C) |

ISO 143/1 |

No Cracking Visible By Eye |

| Change In Hardness |

DIN 53504 |

≤5° |

| Change In Tensile Strength |

DIN 53504 |

≥80% |

| Change In Elongation at Break |

DIN 53504 |

≥80% |

| Minimum Temperature |

- |

-30°C |

| Maximum Temperature |

- |

+70°C |

Features

Superior Impact Absorption

The D Type Fender’s convex profile and high-elasticity rubber enable efficient distribution of kinetic energy from berthing vessels. Even large cargo ships generate minimal stress on hull surfaces, reducing structural damage and repainting requirements. Laboratory tests demonstrate that the fender maintains 90% of its impact-absorbing capacity after 50,000 compression cycles, proving long-term reliability.

Durable Materials and UV Resistance

Constructed from high-quality synthetic rubber, the fender resists abrasion, ozone, and prolonged UV exposure. It maintains elasticity and structural integrity under temperatures ranging from -20°C to 60°C, making it suitable for both tropical and temperate maritime environments. The rubber compound also withstands chemical exposure, such as oil and fuel spills.

Ease of Installation and Maintenance

The flat mounting base allows simple bolted installation onto quay walls, ship sides, or offshore structures. Lightweight sections can be handled manually or with standard lifting equipment. Once installed, the fenders require minimal maintenance, with periodic inspection for wear and tear being sufficient to ensure peak performance.

High Load Capacity and Resilience

D Type Fenders are designed to withstand compressive loads exceeding 3,000 kN/m². The reinforced internal structure prevents permanent deformation, even under repeated heavy impacts, ensuring the fender retains its protective function over years of service.

Applications

Port and Harbor Docking

D Type Fenders are ideal for cargo terminals, container ports, and ferry quays, protecting hulls during routine docking operations. They are suitable for vessels ranging from 1,000 DWT coastal ships to 50,000 DWT medium-sized bulk carriers.

Offshore Oil and Gas Facilities

Used as buffer protection for offshore platforms, jetties, and floating production units, these fenders absorb the impact of support vessels, tugs, and service boats, ensuring operational safety and minimizing downtime.

Shipyards and Dry Docks

During vessel maintenance or dry docking, D Type Fenders act as temporary supports to prevent scratches or structural damage while ships are maneuvered or lifted. Their elasticity accommodates hull curvature and uneven surfaces.

Why Choose Hongruntong Marine

Extensive Industry Experience

Hongruntong Marine has over 15 years of experience in designing and manufacturing marine fenders, supplying ports, shipyards, and offshore facilities worldwide. Our team understands vessel dynamics, docking stress points, and material longevity.

Customized Solutions

We offer tailored fender designs to match vessel type, docking configuration, and environmental conditions. Clients can select height, width, hardness, and mounting options to achieve optimal performance.

Premium Materials and Advanced Manufacturing

Our D Type Fenders use high-grade rubber compounds and reinforced cores, ensuring durability and resistance to extreme marine conditions. Advanced vulcanization and quality control guarantee consistency and long service life.

Comprehensive After-Sales Support

Hongruntong Marine provides technical guidance during installation, maintenance recommendations, and fast replacement services. We ensure that our clients maximize operational efficiency and fender longevity.

FAQ

1. What materials are D Type Fenders made from?

D Type Fenders are manufactured from high-grade synthetic rubber reinforced with inner layers for strength, elasticity, and wear resistance. The compound is UV- and ozone-resistant, suitable for harsh marine environments.

2. Can D Type Fenders be customized for different vessel sizes?

Yes, we can tailor height, length, diameter, hardness, and mounting options based on vessel tonnage, hull shape, and docking conditions.

3. What is the typical lifespan of a D Type Fender?

With proper maintenance, D Type Fenders can last over 10 years under normal marine conditions, retaining most of their impact-absorbing capacity.

4. Are these fenders suitable for offshore applications?

Absolutely. D Type Fenders are tested for both nearshore and offshore use, capable of handling impacts from service vessels, tugs, and floating platforms.

5. How do I install a D Type Fender?

The fenders feature a flat mounting base compatible with bolted installation. Small sections can be handled manually, while larger units require standard lifting equipment. Detailed installation guides are provided.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!