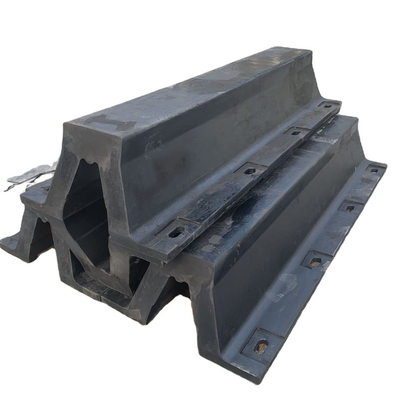

Fender de borracha de qualidade superior forte flexibilidade antienvelhecimento durabilidade a longo prazo

Descrição

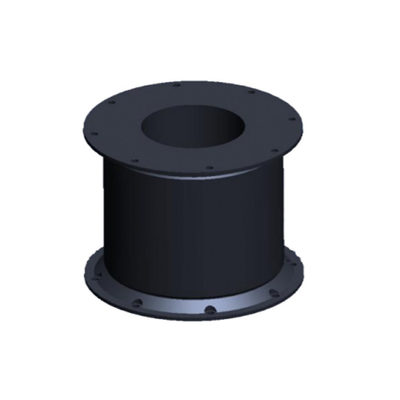

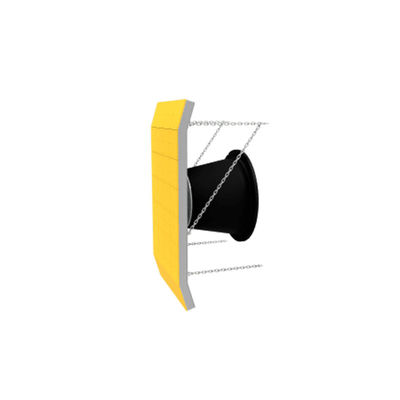

O parafuso de borracha de cone é um parafuso marítimo de alta eficiência projetado para fornecer proteção superior para embarcações e paredes de cais durante o atraque.distribuindo a energia de impacto uniformemente, mantendo uma força de reação baixaA sua dimensão compacta e a sua elevada capacidade de absorção de energia tornam-na adequada para portos com restrições de espaço ou amarras com múltiplas operações de atracação simultâneas.

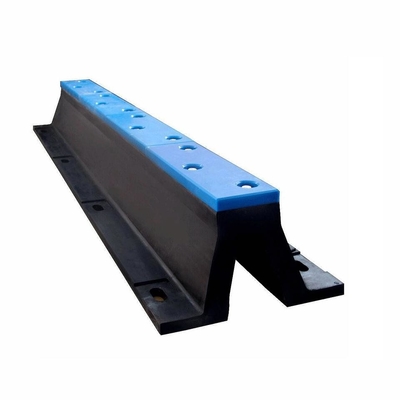

Construído a partir de compostos de borracha natural e sintética reforçados com várias camadas de tecido de cordão de pneu, o guarda-chuvas oferece excelente elasticidade, resistência mecânica,e resistência a condições marinhas adversas, tais como UVAs placas de suporte de aço opcionais e as almofadas UHMW-PE podem ser integradas para melhorar a estabilidade estrutural, reduzir o atrito e prolongar a vida útil.

Estudo de caso: Expansão do terminal de GNL da América do Sul

Um terminal de GNL da América do Sul precisava de uma solução de pára-choques capaz de lidar com grandes navios transportadores de GNL sem causar um esforço excessivo nas paredes do cais.Os guarda-chuvas anteriores tinham mostrado desgaste prematuro e precisavam de substituição frequente, levando a atrasos operacionais.

A Hongruntong Marine forneceu parafusos de borracha cone com placas de apoio de aço reforçado e almofadas frontais UHMW-PE.assegurar uma perturbação mínima das operações de terminais em curso.

Após 18 meses de serviço, os dados de monitorização indicaram uma redução de 45% nas forças de reação de pico durante a atracagem.e as inspecções mostraram desgaste mínimo e nenhuma deformação estruturalOs guarda-chuvas mantiveram a elasticidade e o desempenho, apesar da exposição a correntes fortes, fortes variações de maré e atraques de alta frequência.custos de manutenção reduzidos, e uma vida útil prolongada no cais.

Especificações

| Nome do produto |

Fenders de borracha de cone |

| Nome da marca |

Hongruntong Marine |

| Materiais |

NR de alta qualidade |

| Padrão |

PIANC, HGT |

| Acessórios faciais |

Disponível UHMW-PE |

| Certificados |

BV, ABS, DNV, LR, SGS, RS, CCS |

| OEM / ODM |

Bem-vindo. |

| Detalhes da embalagem |

Sacos de plástico, em seguida, para a palete, conforme o seu pedido. |

| Capacidade de produção |

3000 pcs por mês |

| Tempo de execução |

7 dias para protótipo de ferramentas e amostras, 14 dias para molde de produção, 14-28 dias para MOQ |

| Condições de pagamento |

T/T, L/C, Paypal, Western Union |

| Especificação da borracha |

ASTM D2000, SAE J200 |

| Modelo |

H |

h |

F |

D |

Q |

W |

D-m |

D-n |

| Cone |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

| HM-CRF300 |

300 |

13.5 |

255 |

450 |

195 |

405 |

M16 |

20 |

| HM-CRF350 |

350 |

25 |

300 |

570 |

235 |

510 |

M20 |

25 |

| HM-CRF400 |

400 |

18 |

340 |

600 |

260 |

540 |

M20 |

25 |

| HM-CRF500 |

500 |

25 |

425 |

750 |

325 |

675 |

M24 |

30 |

| HM-CRF600 |

600 |

27 |

510 |

900 |

390 |

810 |

M24 |

30 |

| HM-CRF700 |

700 |

32 |

585 |

1050 |

455 |

945 |

M30 |

38 |

| HM-CRF800 |

800 |

36 |

680 |

1200 |

520 |

1080 |

M36 |

44 |

| HM-CRF900 |

900 |

41 |

765 |

1350 |

585 |

1215 |

M36 |

44 |

| HM-CRF1000 |

1000 |

45 |

850 |

1500 |

650 |

1350 |

M42 |

56 |

| HM-CRF1050 |

1050 |

55 |

1030 |

1680 |

900 |

1530 |

M36 |

44 |

| HM-CRF1100 |

1100 |

50 |

935 |

1650 |

715 |

1485 |

M42 |

50 |

| HM-CRF1150 |

1150 |

52 |

998 |

1725 |

750 |

1550 |

M42 |

56 |

| HM-CRF1200 |

1200 |

54 |

1020 |

1800 |

780 |

1620 |

M42 |

50 |

| HM-CRF1300 |

1300 |

59 |

1105 |

1950 |

845 |

1755 |

M48 |

60 |

| HM-CRF1400 |

1400 |

66 |

1190 |

2100 |

930 |

1890 |

M48 |

60 |

| HM-CRF1600 |

1600 |

72 |

1360 |

2400 |

1060 |

2160 |

M48 |

70 |

| HM-CRF1800 |

1800 |

78 |

1530 |

2880 |

1190 |

2430 |

M56 |

76 |

| HM-CRF2000 |

2000 |

80 |

1900 |

3200 |

1540 |

2920 |

M56 |

76 |

Características

Absorção e redução eficientes da energia e da força de reação

O projeto cônico permite uma compressão gradual, absorvendo eficientemente a energia do impacto, minimizando as forças de reação nas paredes do cais e nas embarcações.,aumentar a segurança e reduzir os custos de manutenção.

Borracha durável e reforço

O guarda-roupa é feito de uma mistura exclusiva de borracha natural e sintética, fornecendo resistência à corrosão por UV, ozônio e água salgada.e capacidade de absorção de energia mesmo em milhares de ciclos de atracamento.

Reforços estruturais resistentes à corrosão

As camadas internas de tecido sintético combinadas com placas de apoio de aço opcionais proporcionam uma elevada estabilidade estrutural e evitam deformações excessivas.Os reforços mantêm a integridade do guarda-chuva sob impactos em ângulo ou de alta energia, prolongando a vida útil e assegurando a fiabilidade operacional.

Construção modular e facilidade de manutenção

O projeto modular permite instalação, substituição e ajuste flexíveis.Sistemas de montagem normalizados e furos pré-perfurados simplificam a instalação e reduzem o tempo de inatividade operacionalAs inspecções regulares e a manutenção são simples devido às superfícies lisas e aos componentes acessíveis.

Aplicações

Terminais de GNL e petróleo

Fornece uma proteção fiável aos petroleiros e transportadores de GNL, reduzindo as forças de impacto nas paredes do cais e no casco do navio durante as operações de atracação.

Portos de carga a granel e de carga geral

Absorve eficientemente a energia durante o atraque de navios de carga a granel, navios de contentores e navios polivalentes, garantindo uma acoplagem suave e a segurança do cais.

Instalações de apoio navais e offshore

Protege navios navais, barcos de patrulha e navios de abastecimento offshore de danos durante atraques de alta frequência, mantendo a prontidão operacional e a segurança portuária.

Por que escolher Hongruntong Marine

Engenharia Avançada e Simulação

Hongruntong usa análise de elementos finitos e simulações de energia de impacto para projetar guarda-chuvas adaptadas ao tamanho do navio, layout de atracação e variações de maré.Força de reação baixa, e durabilidade a longo prazo.

Materiais de primeira qualidade e excelência na fabricação

Usando compostos de borracha proprietários e vulcanização precisa, os Cone Fenders alcançam densidade uniforme, alta resistência à tração e elasticidade a longo prazo.Reforço de várias camadas melhora a resistência à fadiga, permitindo milhares de atraques sem degradação do desempenho.

Soluções personalizadas para os requisitos específicos dos portos

A altura do guarda-chuva, o diâmetro da base, as almofadas de frente e os sistemas de montagem podem ser personalizados para combinar com a geometria do cais, os tipos de embarcações e as condições ambientais.Placas de apoio de aço opcionais e painéis UHMW-PE proporcionam maior segurança e redução do atrito.

Serviço global abrangente

A Hongruntong fornece suporte mundial, incluindo supervisão de instalação, inspeção, renovação e fornecimento de peças de reposição.Programas de manutenção preditivos e orientações técnicas ajudam a garantir um desempenho confiável a longo prazo e a minimizar o tempo de inatividade operacional.

Perguntas frequentes

1Qual é a duração típica de uma bala de borracha de cone?

A vida útil esperada é de 12 a 20 anos, dependendo do uso, das condições ambientais e das práticas de manutenção.

2Os Cone Fenders podem lidar com atraques frequentes?

Sim, a geometria cônica e a estrutura reforçada permitem atracar frequentemente sem danos estruturais ou perda de desempenho.

3São necessárias almofadas?

As almofadas opcionais UHMW-PE reduzem o atrito e protegem os revestimentos do casco do navio, melhorando a segurança e o desempenho.

4Estes guarda-chuvas podem ser montados em cais de aço ou concreto?

Sim, os sistemas de montagem normalizados e as placas de apoio de aço opcionais permitem uma instalação flexível em ambos os tipos de cais.

5Que tipo de manutenção é recomendada?

Inspeções visuais regulares a cada seis meses e verificações anuais pormenorizadas de desgaste da superfície, integridade da montagem e estabilidade do reforço.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!